• OPERATING HEIGHT: Will present pipe from ground to work floor from 4’ to 40’ high.

• HYDRAULIC RACKS: Level, tilted toward or tilted away from Glider; allows gravity feed, touch-free pipe handling.

• PROGRAMMED WORKFLOOR HEIGHT: Preset height at job setup repeats automatically for each joint presentation.

• RABBIT DROP POSITION: Preset position at job setup repeats automatically for each joint presentation.

• ELEVATOR LATCH POSITION: Preset movement into work floor initiated by operator with toggle on wireless remote for more safety.

• START NEXT CYCLE: Operator starts next cycle with toggle on wireless remote for more safety.

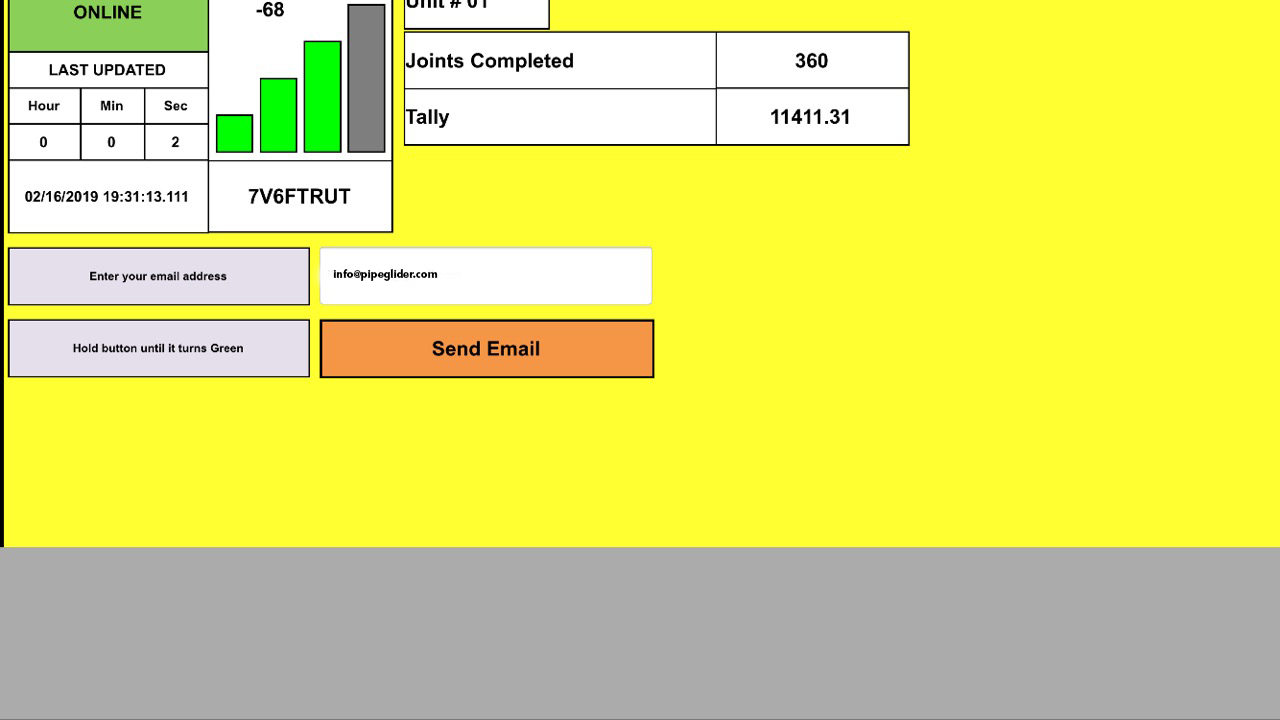

• ELECTRONIC TALLY: Pipe measured during movement; joint count and length put on large display, website, and jump drive.

• DEPTH ALERT: At setup, depths of gas lift subs, plugs, etc. are programmed; auditory and visual alarms when depth reached.

• CYCLE TIME: System tracks elevator latch to elevator latch time; records visible only on website.

• SILENT PACK DIESEL ENGINE: Latest technology significantly reduces worksite noise level.

Introducing Pipe to Floor

• The trough begins to move up as the skate initiates the pipe measuring sequence. The trough automatically stops at the work floor height. The pipe will not move past the end of the trough until the operator tells it to.

Pipe Tally

• The automated tally system keeps track of every joint. The pipe tally can be downloaded onto a flash drive or be accessed remotely by logging on to a website.

LED Display and Pipe Tally

• Bright LED display that shows the current joint number and depth. The LED display can be read up to 300’ away.

THE GLIDER PIPE HANDLER OFFERS TWO HANDLING SYSTEMS

HYDRAULIC PIPE RACKS and HYDRAULIC PIPE TUBS

- The Glider and racks are positioned

on-site as depicted here. - 26 feet long

- Hydraulically adjustable height from 35” to 46”

- Weight capacity of 18000 pounds per rack pair

- Hands free delivery of pipe to the work floor

- Hydraulically controlled to tilt towards the Glider to allow pipe to roll on its own

- Hydraulically controlled to tilt away from the glider when pulling out of the hole

- Hydraulic indexing mechanism feeds one pipe at a time to the Glider

- Adjusts to pipe sizes ranging from 2 3/8 to 5 ½”

- compatible with existing pipe racks

- The Glider and tubs are positioned

on-site as depicted here. The red primary

tub is positioned directly next to the

glider the secondary tubs are positioned

next the primary tub (4 tubs totaling a

50’ x 60’ footprint.) - Four hydraulic landing gear allow

the tubs to be angled towards or

away from the Glider for loading and

unloading. - Each pipe tub can hold up to 6272 feet of

2 3/8” pipe or 4608 feet of 2 7/8”. Two

tubs loaded with 2 3/8” and two tubs loaded

with 2 7/8” total up to 21,700 feet of pipe.

VIDEO PRESENTATION OVERVIEW WITH TESTIMONIALS

Select the image below for VIDEO and TESTIMONIAL, or click here https://youtu.be/Z-GDwjYL3vc

Select the image below for a brief representation of Glider features, or click https://youtu.be/2XmXVZVGTvE

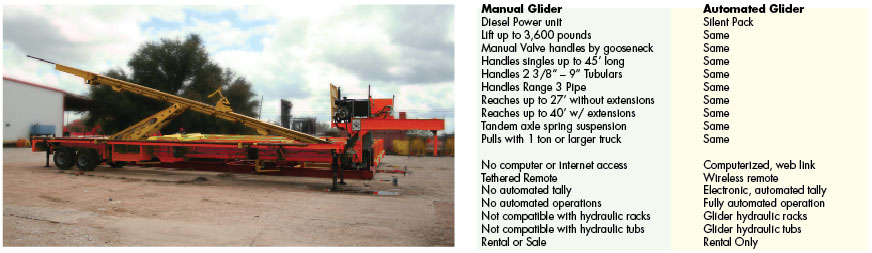

MANUAL PIPE GLIDER ALSO AVAILABLE

Product Features : Manual Glider -vs- Automated Glider

Call Today for Availability and Updated Information...

Please feel free to contact us for further information on our Pipe Handling System. We would love to discuss the possibilities to work with you.